|

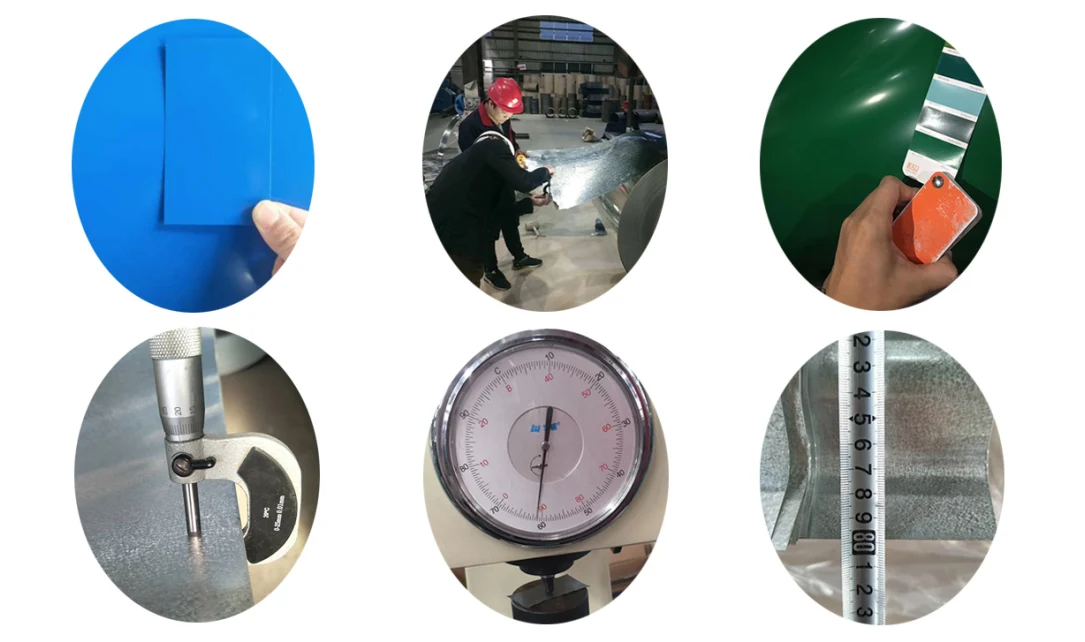

Our factory has multiple production lines, with a monthly output of several thousand tons. At the same time, cutting and cutting equipment can be cut flat. Spot wholesale guarantee product quality intimate service The company's technical force, the processing equipment of processing technology, diverse processing methods, can provide users with aluminum plate shear cleaning ruler processing, aluminum bands longitudinal partial processing, thickness in aluminum alloy Panel sawtage ruler processing, aluminum plate surface covering processing, etc., to meet the needs of users with small batches, multi -varieties, multi -specifications, and multi -purpose needs Real materials and real materials are uniform performance stable performance. Have a lot of stocks, product quality assurance. Refinery for many years of industry experience is worthy of your trust

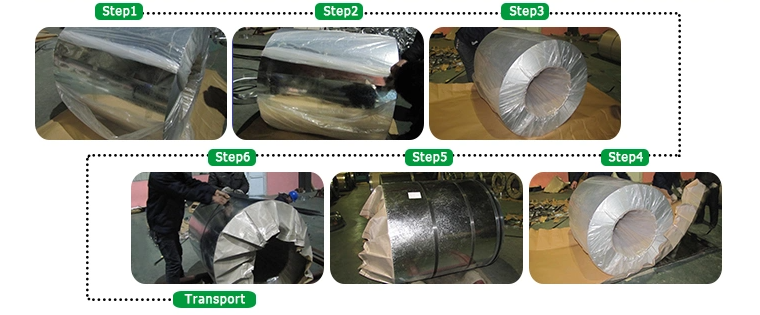

Our factory has multiple production lines, with a monthly output of several thousand tons. At the same time, cutting and cutting equipment can be cut flat. Spot wholesale guarantee product quality intimate service The company's technical force, the processing equipment of processing technology, diverse processing methods, can provide users with aluminum plate shear cleaning ruler processing, aluminum bands longitudinal partial processing, thickness in aluminum alloy Panel sawtage ruler processing, aluminum plate surface covering processing, etc., to meet the needs of users with small batches, multi -varieties, multi -specifications, and multi -purpose needs Real materials and real materials are uniform performance stable performance. Have a lot of stocks, product quality assurance. Refinery for many years of industry experience is worthy of your trust Based on high quality and warmly service, we have won clients all over the world, our products are widely trans to USA, Euro, India, Iran, Dubai, Russia, Thailand, South America, Singapore, and so on.Wrap with special anti rust paper; Covered with plastic film, packed with steel belt or wooden pallet or packed according to customer requirements.We have long-term cooperation with many experienced shipping companies and will find the most suitable mode of transportation for you.Standard Export Package, Ensure the High Quality Delivery.

Based on high quality and warmly service, we have won clients all over the world, our products are widely trans to USA, Euro, India, Iran, Dubai, Russia, Thailand, South America, Singapore, and so on.Wrap with special anti rust paper; Covered with plastic film, packed with steel belt or wooden pallet or packed according to customer requirements.We have long-term cooperation with many experienced shipping companies and will find the most suitable mode of transportation for you.Standard Export Package, Ensure the High Quality Delivery.

| Packaging Details: | Standard seaworthy packing(plastic&wooden) or according to the customer's requests |

| Delivery Detail: | 3-10days, mainly decided by the quantity of the order |

| Port: | Tianjing/Shanghai |

| shipping | Sea ship by container |

Q1:Can I get samples before order ? A:Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings. Q2:Can I go to your factory to visit? A:Of course, we welcome customers from all over the world to visit our factory. Q3:What product information do I need to provide? A:You need to provide the grade, length, width, diameter, thickness, coating and the number of tons you need to purchase. Q4:Does the product have quality inspection before loading? A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.we accept third party inspection. Q5:How do we trust your company? A:We specialise in steel business for years , headquarter locates in Jinan, Shandong province, you are welcome to investigate in any ways, by all means, we have CE and ISO certificate, quality can be guaranteed, the most important point is that we ship enough weight as per the order.

Q1:Can I get samples before order ? A:Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings. Q2:Can I go to your factory to visit? A:Of course, we welcome customers from all over the world to visit our factory. Q3:What product information do I need to provide? A:You need to provide the grade, length, width, diameter, thickness, coating and the number of tons you need to purchase. Q4:Does the product have quality inspection before loading? A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.we accept third party inspection. Q5:How do we trust your company? A:We specialise in steel business for years , headquarter locates in Jinan, Shandong province, you are welcome to investigate in any ways, by all means, we have CE and ISO certificate, quality can be guaranteed, the most important point is that we ship enough weight as per the order. 1.Send inquiry directly. 2.Send email. 3.Contacting via phone. 4.Contact sales staff.

1.Send inquiry directly. 2.Send email. 3.Contacting via phone. 4.Contact sales staff.