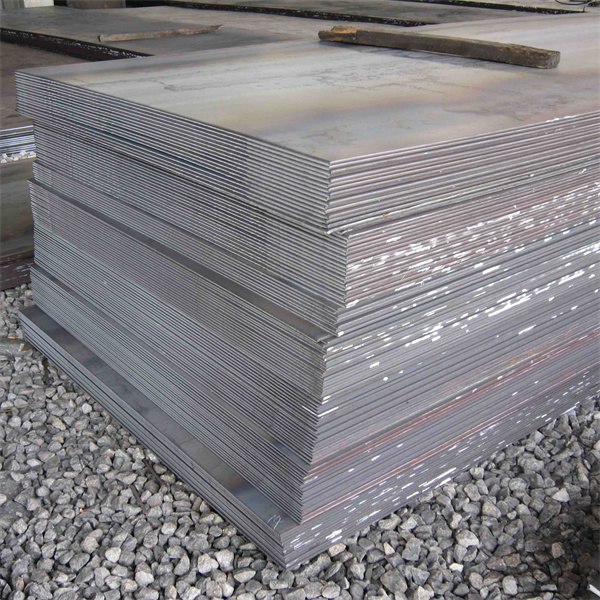

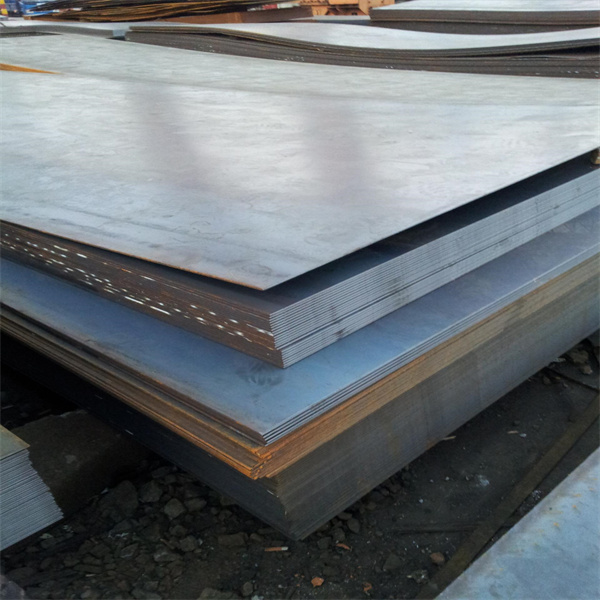

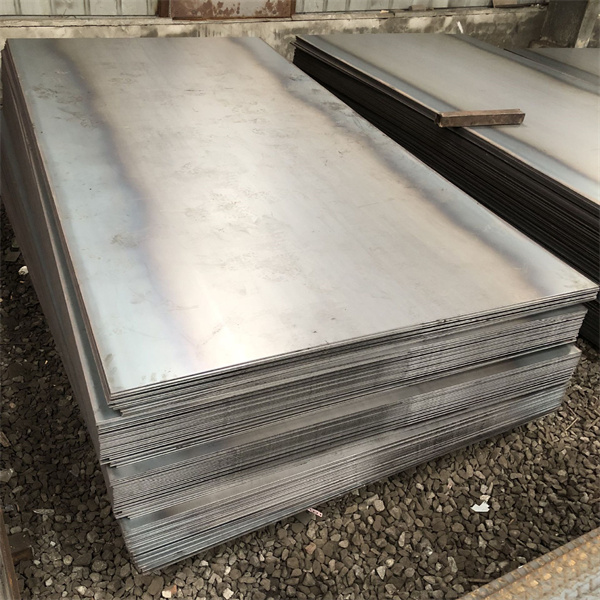

The hot-rolled steel plate is made of continuous casting slab or blooming slab as raw material, which is heated in a walking furnace, descaled by high-pressure water, and then enters the rough rolling mill. Rolling, after the final rolling, it goes through laminar cooling (computer-controlled cooling rate) and coiling by a coiler to become a straight coil. The head and tail of the straight hair curler are often tongue-shaped and fish-tail-shaped, with poor thickness and width accuracy, and the edges often have defects such as wave shape, folded edge, and tower shape. The coil weight is heavier, and the inner diameter of the steel coil is 760mm. After the straight hair coil is processed by cutting head, tail cutting, edge trimming and multi-pass straightening, leveling and other finishing lines, it is then cut or re-coiled to become: hot-rolled steel plate, flat hot-rolled steel coil, longitudinal Tape and other products.

The hot-rolled steel plate is made of continuous casting slab or blooming slab as raw material, which is heated in a walking furnace, descaled by high-pressure water, and then enters the rough rolling mill. Rolling, after the final rolling, it goes through laminar cooling (computer-controlled cooling rate) and coiling by a coiler to become a straight coil. The head and tail of the straight hair curler are often tongue-shaped and fish-tail-shaped, with poor thickness and width accuracy, and the edges often have defects such as wave shape, folded edge, and tower shape. The coil weight is heavier, and the inner diameter of the steel coil is 760mm. After the straight hair coil is processed by cutting head, tail cutting, edge trimming and multi-pass straightening, leveling and other finishing lines, it is then cut or re-coiled to become: hot-rolled steel plate, flat hot-rolled steel coil, longitudinal Tape and other products.