Product features: Due to no annealing treatment, high hardness (HRB > 90), poor machinability, can only be carried out below 90 degrees of simple directional bending (perpendicular to the coiling direction). To put it simply, cold rolling is processed and rolled on the basis of hot rolled coil. Generally speaking, it is a hot rolling - pickling - cold rolling process. Cold rolled sheet is processed from hot rolled sheet at room temperature. Although the temperature of the steel plate will rise during processing, it is still called cold rolling.

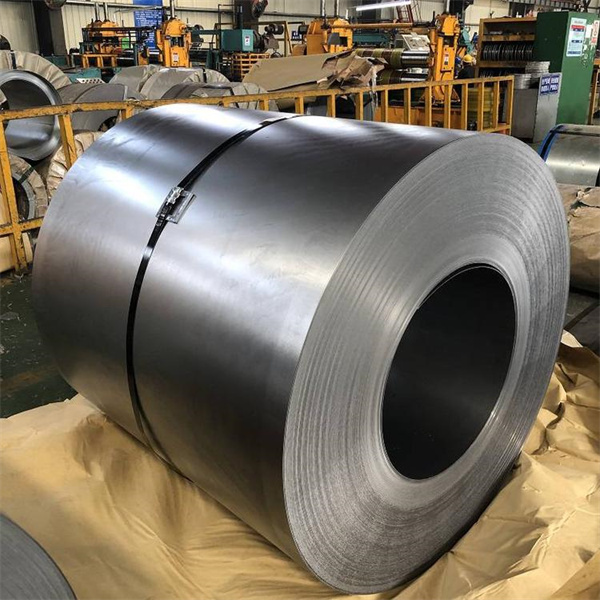

Product features: Due to no annealing treatment, high hardness (HRB > 90), poor machinability, can only be carried out below 90 degrees of simple directional bending (perpendicular to the coiling direction). To put it simply, cold rolling is processed and rolled on the basis of hot rolled coil. Generally speaking, it is a hot rolling - pickling - cold rolling process. Cold rolled sheet is processed from hot rolled sheet at room temperature. Although the temperature of the steel plate will rise during processing, it is still called cold rolling.  Due to continuous cold deformation of hot rolling, mechanical properties are poor and hardness is too high. It must be annealed to restore its mechanical properties, and those without annealed are called hard rolled coils. Hard rolled coils are generally used to make products that do not need to be bent or stretched. Coils with thickness less than 1.0 are rolled on both sides or four sides, with good luck. Application: Cold rolled strip is widely used in automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, canned food, etc.

Due to continuous cold deformation of hot rolling, mechanical properties are poor and hardness is too high. It must be annealed to restore its mechanical properties, and those without annealed are called hard rolled coils. Hard rolled coils are generally used to make products that do not need to be bent or stretched. Coils with thickness less than 1.0 are rolled on both sides or four sides, with good luck. Application: Cold rolled strip is widely used in automobile manufacturing, electrical products, rolling stock, aviation, precision instruments, canned food, etc.